An ISO 9001:2015 certified company, Lincoln Plastics, formerly Geist Plastics has been on the cutting edge of manufacturing custom plastic profile extrusions since 1948. Lincoln Plastics has achieved a level of quality and service that is unsurpassed in the plastic profile industry.

Quality control involves testing units and determining if they are within the specifications for the final product. The purpose of the testing is to determine any needs for corrective actions in the manufacturing process. Good quality control helps companies meet consumer demands for better products.

From the buyer’s perspective, quality control activities help confirm that a batch of products meet specifications. The most common activity is the final inspection, which means checking some products against a checklist, and getting to a pass/fail result.

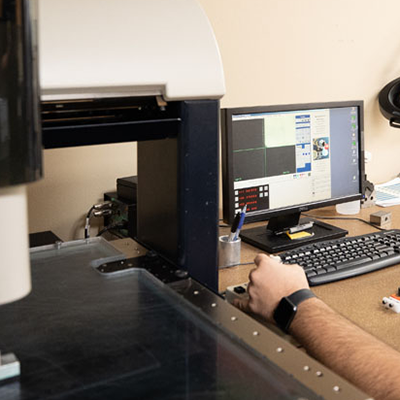

Quality parts, resin, equipment, just-in-time capabilities, and people are only part of the total quality picture. We are a plastic profile extrusion company with standardized quality and lean manufacturing practices with a quality management system certified to the ISO 9001:2015 standard. In addition, our Quality Assurance System is in place to expand “Quality” to total customer satisfaction.

To ensure that quality is more than a buzzword, we have implemented a comprehensive quality management system to translate our commitment to a finite and exacting discipline. That commitment, coupled with our statistical process Control program ensures strict compliance with your custom specifications.

Quality management ensures that an organization, product or service consistently functions well. It has four main components: quality planning, quality assurance, quality control and quality improvement. Quality management is focused not only on product and service quality, but also on the means to achieve it.